When considering hardwood flooring for your home, some important considerations are the hardness of the wood species, how the floor will be installed and how to keep the floor looking like new.

Hardwood Species and Hardness

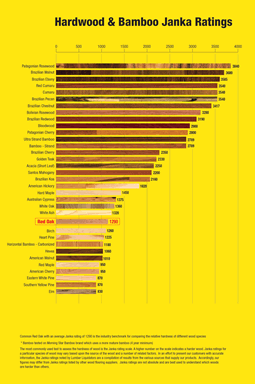

Each type of wood flooring has its own cell structure that creates its own physical properties that determines its suitability for various applications. The hardness of hard woods will vary greatly and some hardwoods are not suitable for flooring simply because they are not hard enough to with stand the wear and tear. The Janka Scale of Hardness is an excellent tool for making the best decisions (See chart).

Hardwoods

North America’s forests grow hundreds of varieties of hardwood (deciduous trees) like ash, oak, maple, poplar, cherry, etc. The grain patters, texture and color vary significantly.

Tropical Hardwoods

Including mahogany, rosewood, teak and wenge, these hardwoods are not native to North America. These hardwoods grow in tropical rain forests and are imported for use in the U.S.. These species of wood differ from our native hardwoods in color, grain pattern and luster.

Hardwood Flooring Maintenance

Here are a few things NOT to do in maintaining your wood flooring:

- Never use vinyl or tile floor care products on your hardwood floor.

- These products (acrylic waxes) can become slippery and dull quickly.

- Do not wet mop your hardwood floor. This can dull the finish, damage and discolor the wood.

- Be careful not to over wax your floor. If the wax does dull you can sometimes buff the floor out.

- Do not walk on a hardwood floor with high heel shoes or sports shoes. This kind of impact can dent any floor considering the force being close to 2,000 lb. per inch. An exposed heel nail can exert 8,000 pounds per square inch on your floor.

- Do not slide furniture over a wood floor even though this may be the easiest way to move the furniture. This will prevent scratches.

Here are a few things you want to do in maintaining your wood flooring:

- Use throw rugs on your wood floor inside and outside entry/exit points. This will minimize dirt and grit and ultimately help prevent scratches.

- Wipe up spills quickly with a damp towel.

- Only use approved products in cleaning or polishing your floor. When in doubt apply the product to an obscure patch before spreading over the floor.

- Use stick on felt protectors on your furniture to prevent scuffing. Replacing the pad frequently to avoid dirt build up and scratching of your floor.

- Use a humidifier in the winter to help to minimize gaps or cracks in the floor.

Hardwood Flooring Installation Methods

Nail / Staple Down

This installation method is typically done with a pneumatic nail/staple gun. Not all manufacturers recommend the same staple gun. Using a professional installer will insure that the proper gun and staples/nails are used in the installation. ¾” solid wood planks (or strips) are installed by using a 2” nailing cleats attaching them to a subfloor. Solid wood products can only be nailed to wooded subfloors.

Glue Down

In this method of installation it is critical to be sure that the manufacturers recommended adhesive and trowel size is used. Failure to use the approved adhesive and trowel size could void the warranty on your floor. This method of installation is used to install engineered and parquet floors since solid hardwoods can only be nailed/stapled down. The adhesive or natural resin is called “Mastic” and is spread over the subfloor with the proper trowel.

Floating Floor

This method of installation is quite different from the other two methods. With the floating floor, the actual floor is not mechanically fastened to the subfloor. The hardwood is installed over a thin pad on top of the subfloor. On each strip or plank the glue is applied to the tongue and groove to hold the pieces together. There are some advantages to having a floating floor like the protection from moisture, reduction in noise transmission and it is softer underfoot. There are some engineered floors and all of the long strip floors can be floated.

HAVE QUESTIONS ABOUT HARDWOOD FLOORING?

If you have any inquiries about hardwood flooring or any of our installation services, we are here to answer all of your questions at any time.

Get in touch with us